22/10/2025

The LCA Skeleton

Inside the Heart of a Positive Displacement Diaphragm Pump: A Look at the Engineering Simplicity

Authors: Diego Achotegui, Applications Sales Engineer, of Industrial Flow of North America. Steven Tabb, Technical Support and Sales Specialist, of Industrial Flow of North America.

We want to show just how intuitive our pumps are. No complicated internals. No mystery. Just straightforward engineering that keeps your operations flowing.

Whether you’re a plant technician, maintenance engineer, or facility manager, you’ll appreciate how easy these are to service, inspect, and get back online. Today, we're taking you inside one of the most critical pieces of industrial equipment we supply: the LEWA ecosmart.

In this post, we’re going to walk you through the internal components of a LEWA ecosmart-LCA that has been in service for 4 years (non-stop) to show you just how simple, robust, and serviceable these units are.

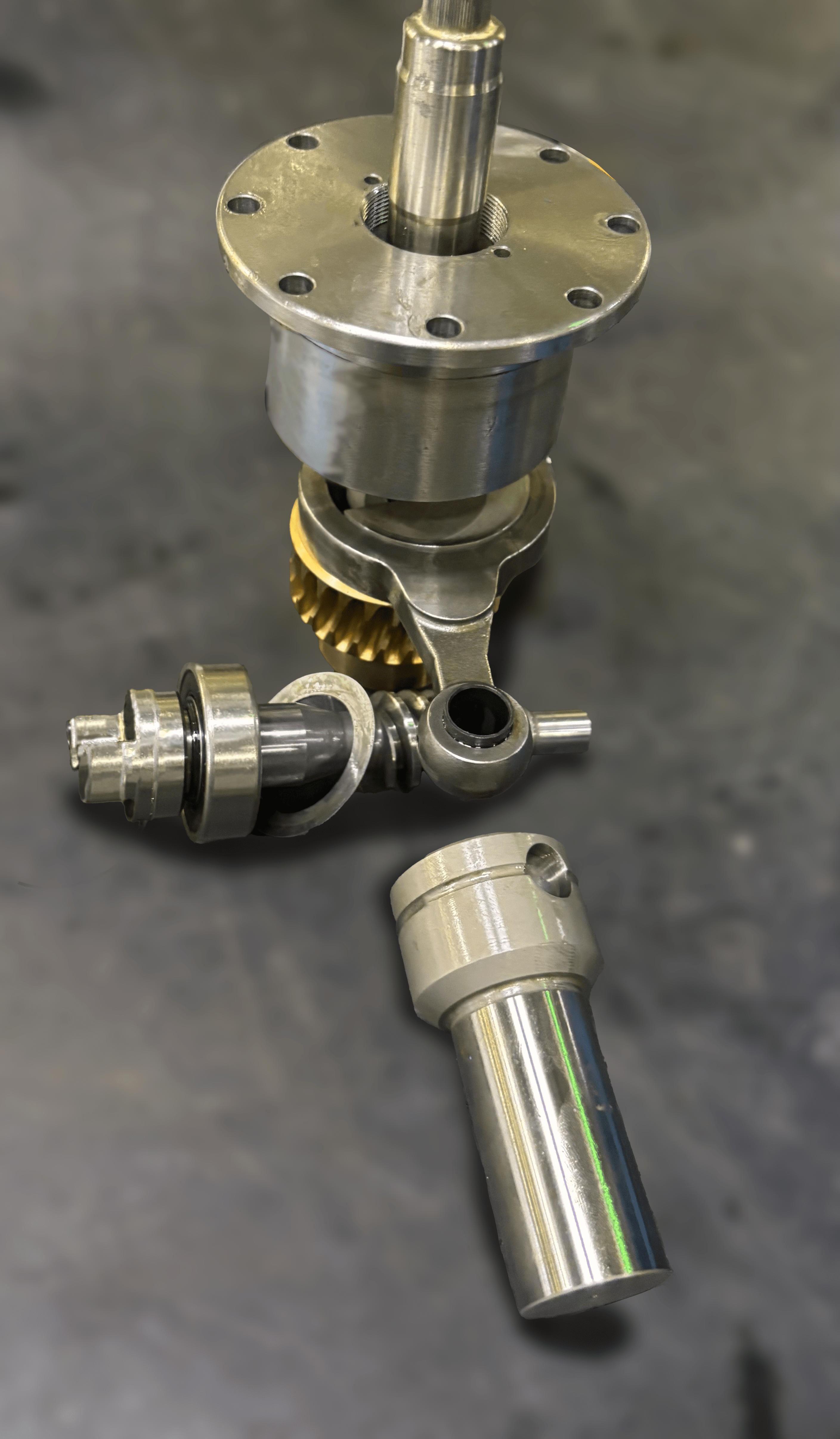

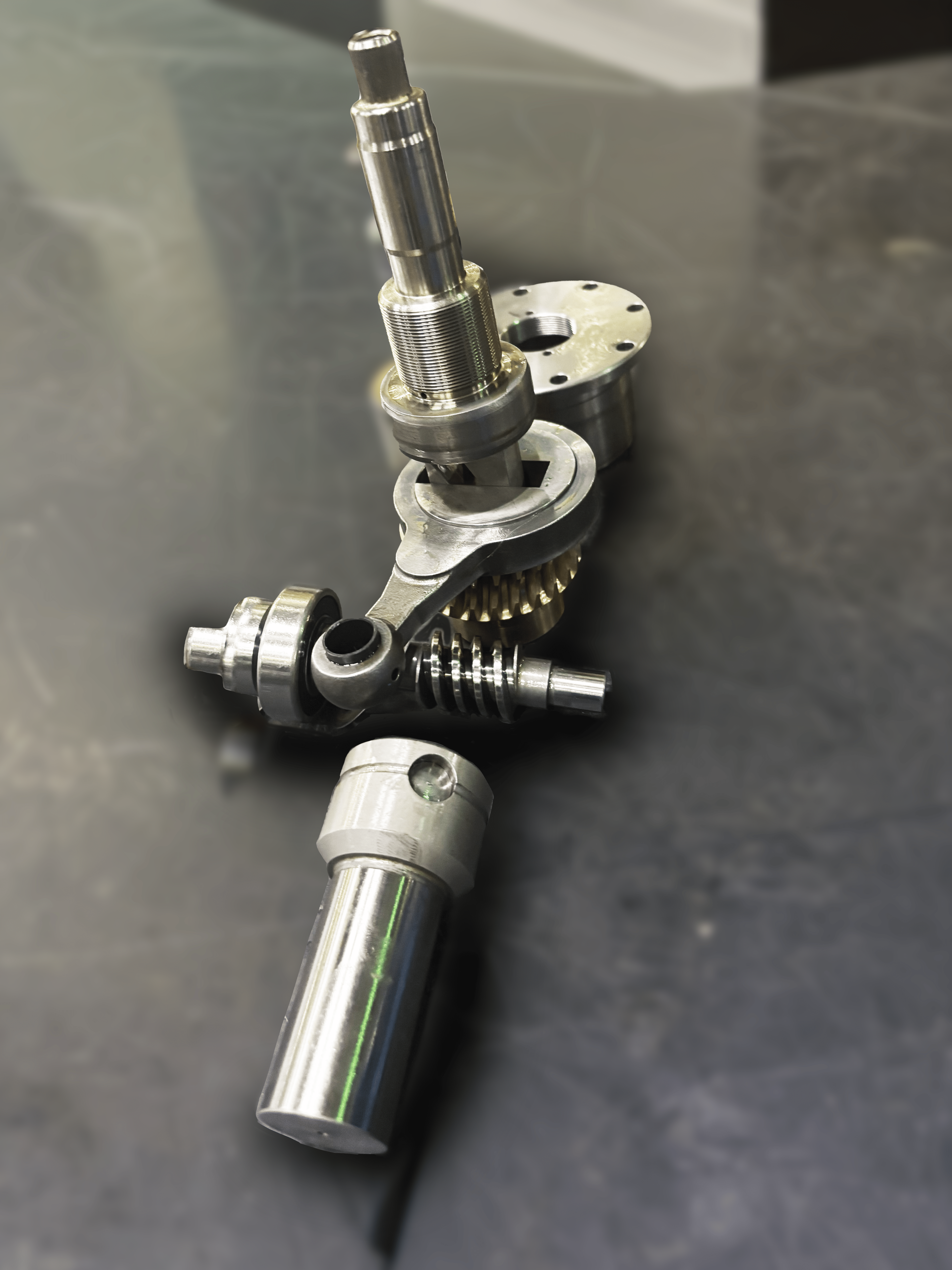

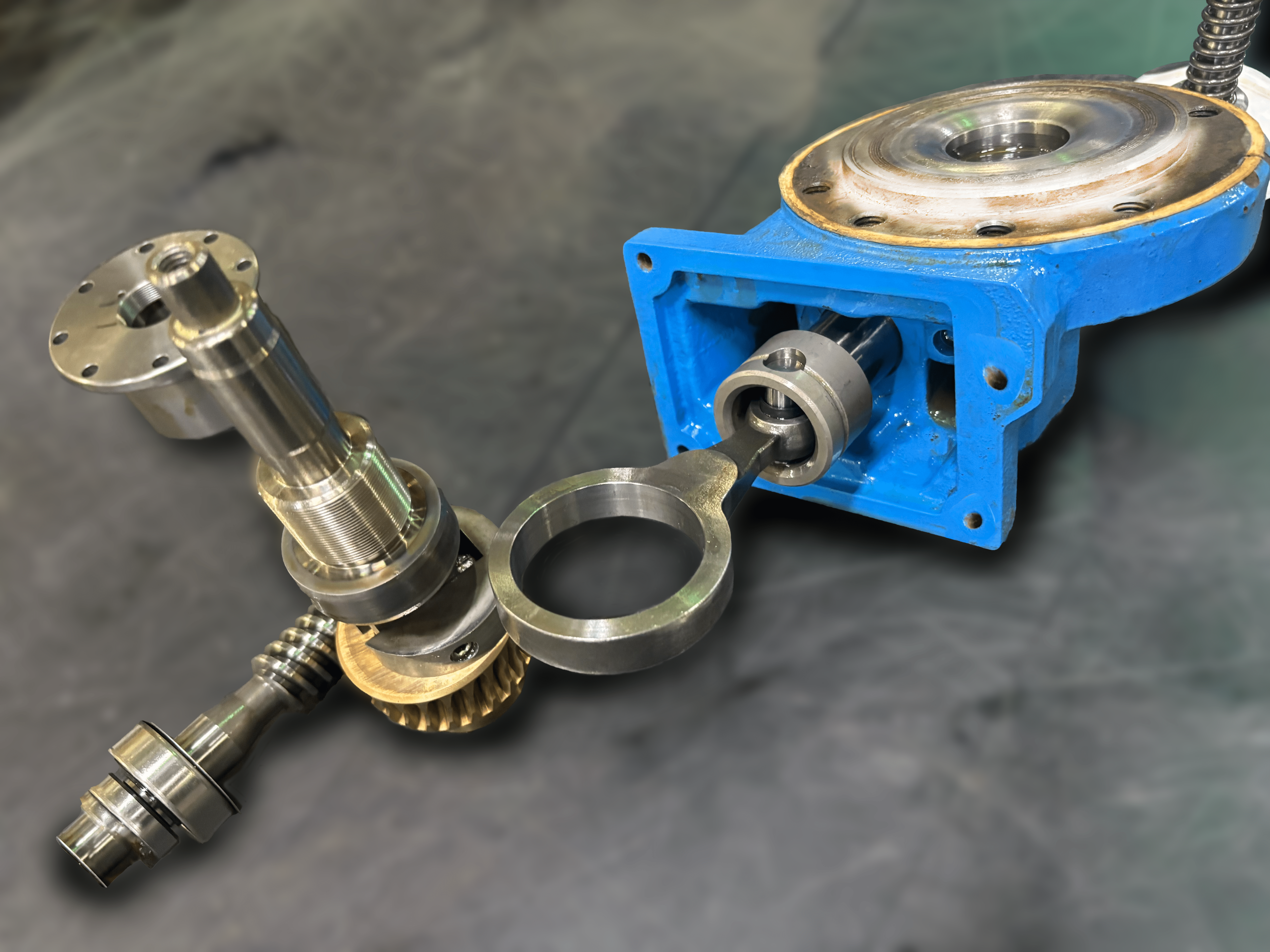

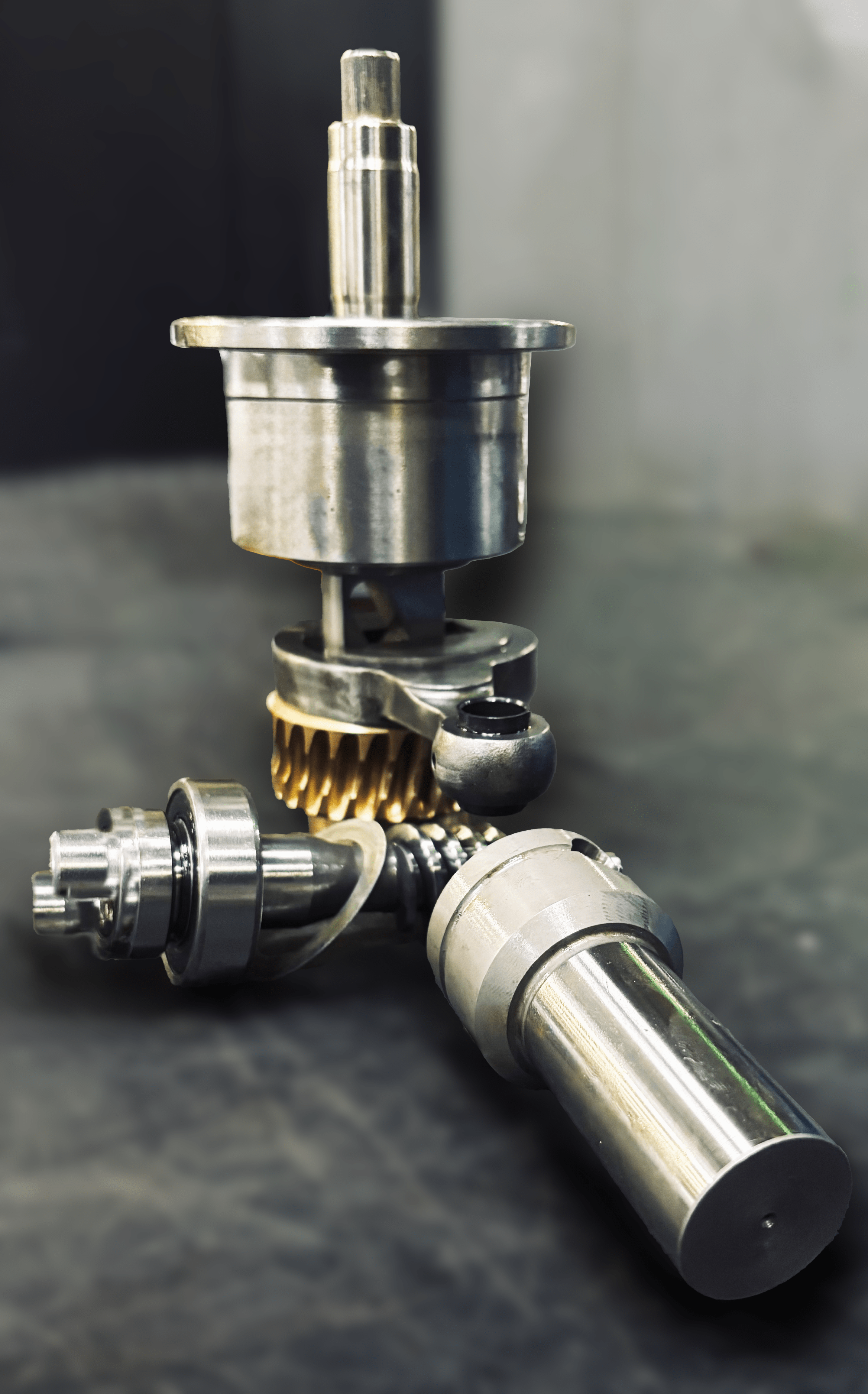

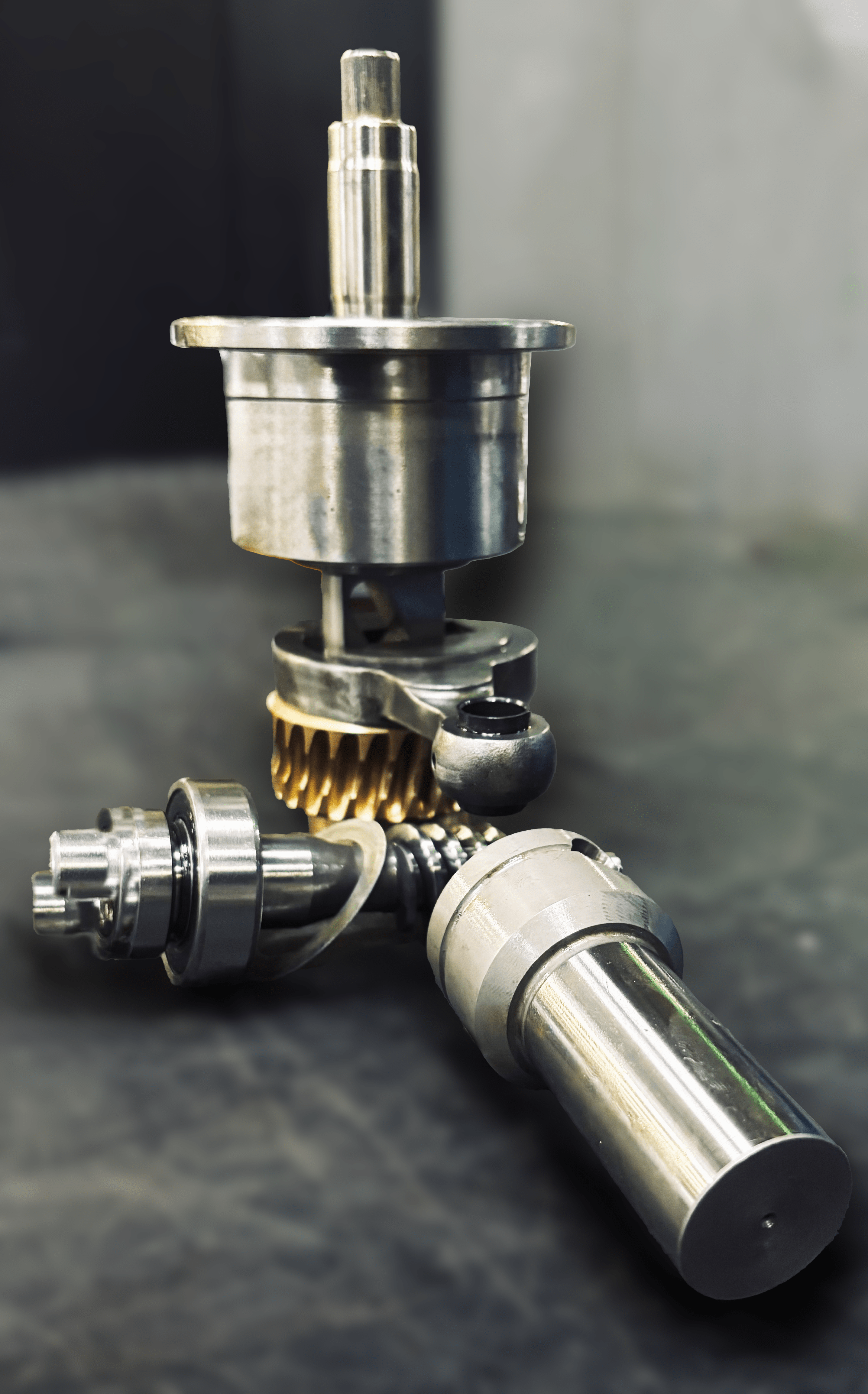

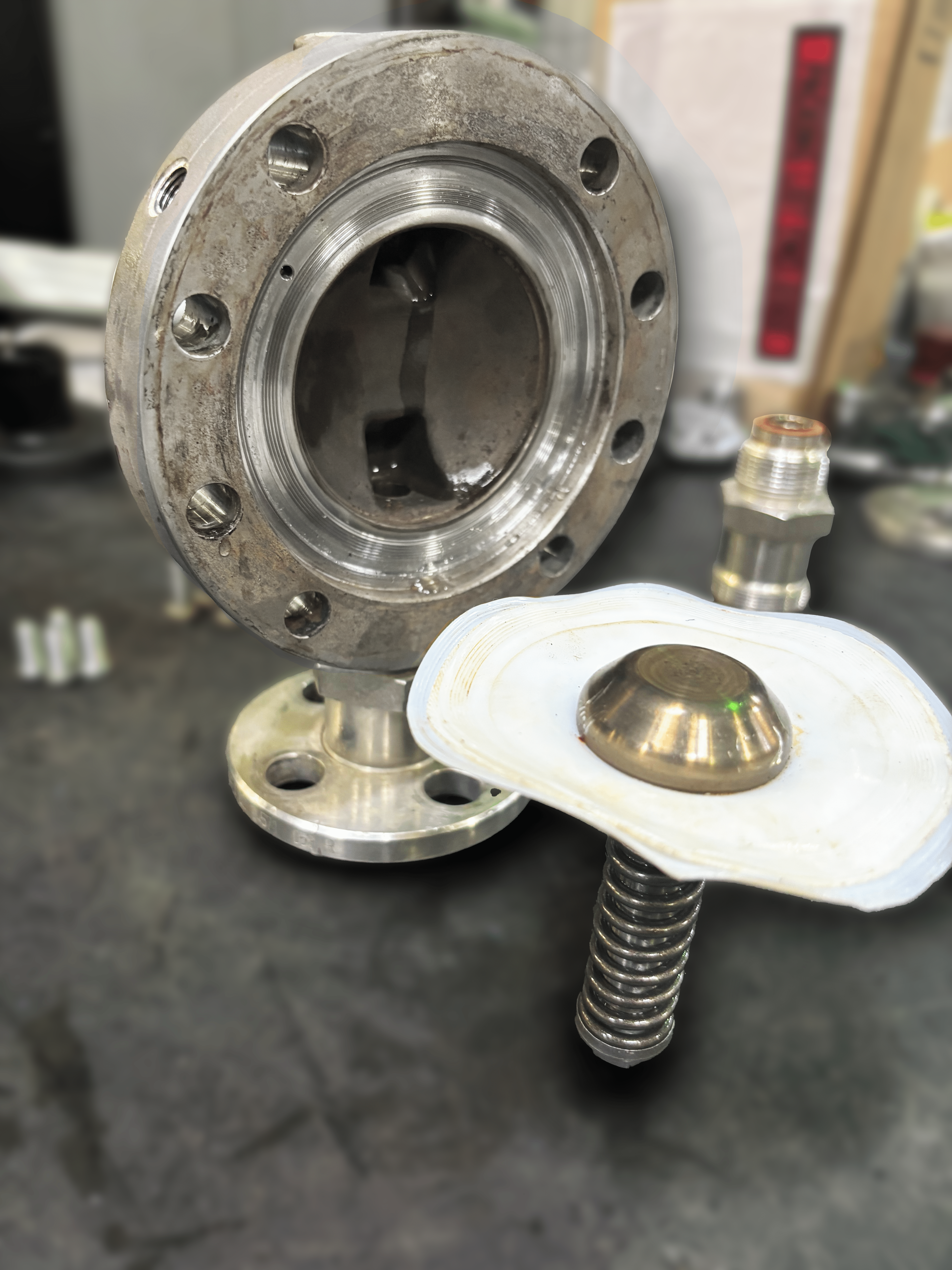

Breaking It Down: The Internal Components (Picture 1 & 2)

Here on the workbench, you can see the fully disassembled core of a LEWA ecosmart-LCA. Let’s go through the major components:

1. Crankshaft & Connecting Rod Assembly

This is the "engine" of the pump. The crankshaft converts the rotary motion from the drive motor into reciprocating motion. That motion is transferred to the connecting rod, which drives the diaphragm back and forth.

• Precision machining ensures smooth rotation.

• Sturdy bronze worm gear for torque transfer and durability.

• Oil bath lubrication for longevity and smooth operation.

2. Cam Follower, Bearing Assembly & Variable Eccentric Drive

This setup ensures consistent and smooth linear movement. As the cam rotates, it pushes and pulls the follower, translating rotation into diaphragm motion. LEWA uses its proven variable eccentric principle; this also enables easy operation. The stroke length is adjusted directly on the eccentric shaft. The handwheel can be used to make a linear stroke adjustment in 0.05 mm increments, either during standstill or operation. The plungers move in harmony even in the partial stroke range, preventing additional, disruptive pulsations in this range.

• Designed for minimal friction.

• Easily replaceable bearings for fast servicing.

3. Diaphragm & Retainer System

This is the actual pumping element. The sandwich/double diaphragm is clamped by the micro grooves on the diaphragm body and drive. It flexes back and forth to move fluid without allowing contact between the fluid and internal mechanical parts.

• Made from chemical resistant materials (PTFE).

• Spring-loaded design ensures consistent sealing and reliable return action, contributing to reduced NPSH (Net Positive Suction Head) requirements and preventing overflow into the hydraulic chamber.

• LEWA ecosmart pumps offer a double/sandwich diaphragm as standard. This includes a rupture detection system – gauge, pressure switch, and pressure transmitter.

Why This Design Matters

The engineering behind our diaphragm pumps is intentionally minimalist. Fewer moving parts mean:

• Less maintenance

• Lower risk of failure

• Easy troubleshooting

• Quicker part replacement

Whether you're pumping corrosive chemicals, viscous fluids, or clean water, the internal design stays the same: reliable, rugged, and easy to maintain.

Available Now in Our Webshop

Ready to get your hands on this kind of performance and simplicity? Browse our selected range of LEWA ecosmart-LCA diaphragm pumps on our LEWA USA Webshop. We're here to support you with top-tier products and technical know-how.